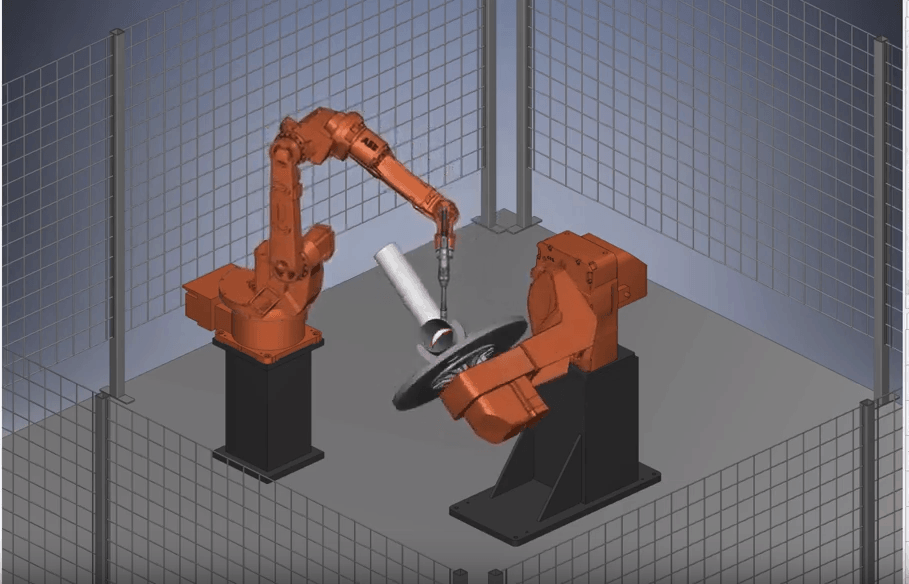

Robot welding working with 3D-Printed Structures

Nowadays, robot welding works with 3D-Printed Structures. Even though, it requires a more complete structure for the robot to operate this is not impossible. 3D-Printed is becoming more popular and robotic welding arms can help to build even large structures. By controlling the point where the welds are made, it’s possible to control the orientation of parts to be welded.