The future of Robotic Automation Systems

The future of robotic automation systems is here with new technologies. It could be the start of a new era of working with robots cooking, robot serving food, robot surgery, or what about robots in the construction, lawyers, architecture design? Who knows what else we will hear about working with robots in the near future!

Robotic Manufacturing Companies

Manufacturing robots refers to a common practice of automating repetitive, tasks across the manufacturing process. The company objective is to reduce manual errors, increase production tasks and save costs.

Why you should invest in robotics & robot automation?

Robot automation & robotics equipment are easier to calculate the Return on Investment (ROI) than when you are investing in a share or stock market.

Manufacturing Robots Dos and Don’ts

Manufacturing robots refers to a common practice of automating repetitive, tasks across the manufacturing process. The company objective is to reduce manual errors, increase production tasks and save costs. There are many manufacturing robots for sale but not all of them suit the automation task you want to achieve.

Industrial Automation New Technology

In recent years industrial automation new technology such as mobile devices are playing an important role in every aspect of our lives and they are increasingly demanding with automation systems changing how data is analysed, stored, and acquired.

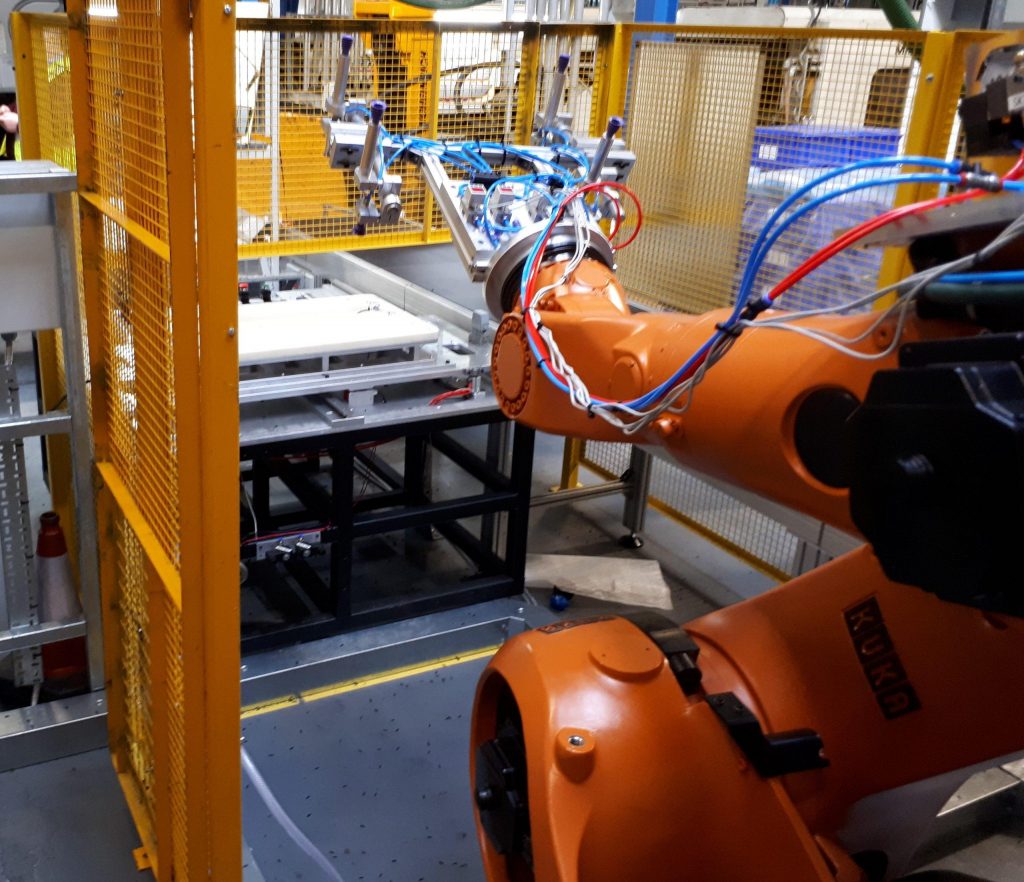

Industrial Automation Systems How to Stay Competitive

Industrial automation systems offer a variety of automation solutions to help manufacturers. Some industrial automation are more complex than others, for this reason, it is imperative to find an industrial automation company with experience in this subject.