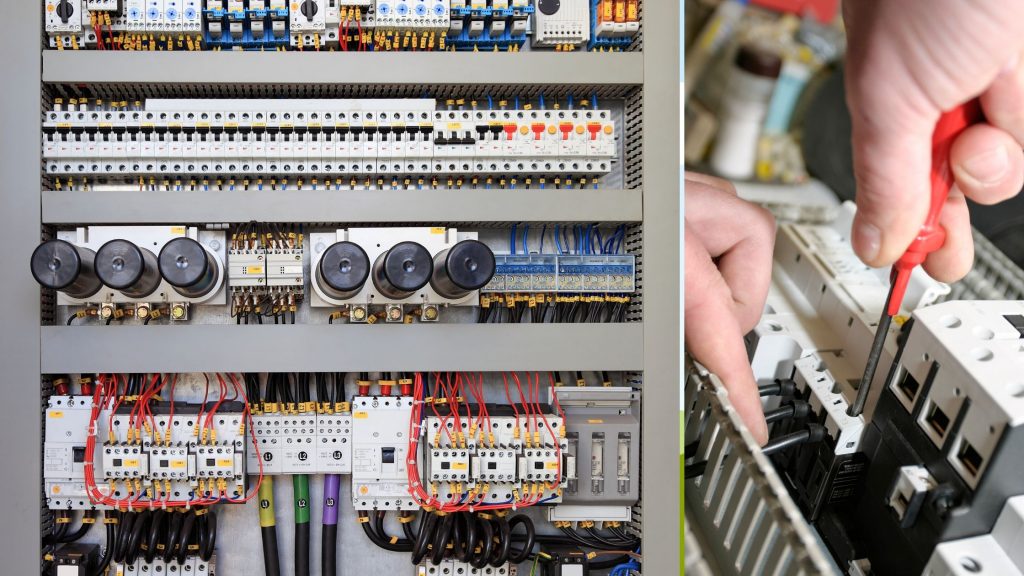

Most frequent mistakes made by control panel manufacturers

Most frequent mistakes made by control panel manufacturers Control Panel manufacturers can build panels, but few can build a long-lasting high-quality industrial control panel. However, control panels are not just one more item for the project. For instance, quality control panel manufacturers are important to production and to maintain the project lifecycle. <p>Above all, the […]

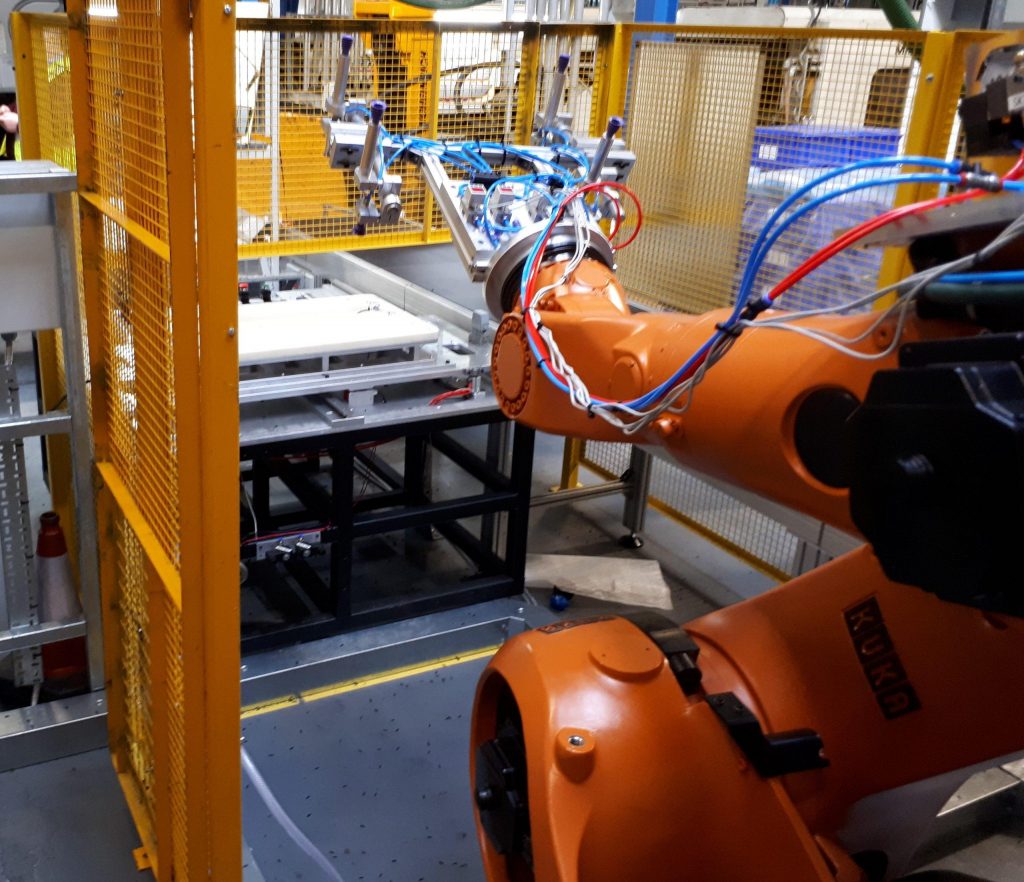

Industrial Automation Systems How to Stay Competitive

Industrial automation systems offer a variety of automation solutions to help manufacturers. Some industrial automation are more complex than others, for this reason, it is imperative to find an industrial automation company with experience in this subject.